-

Water, Waste Water and Organic Waste

Management Company -

email us

info@kelvinindia.in

-

call us now

+91 9812 24 1001

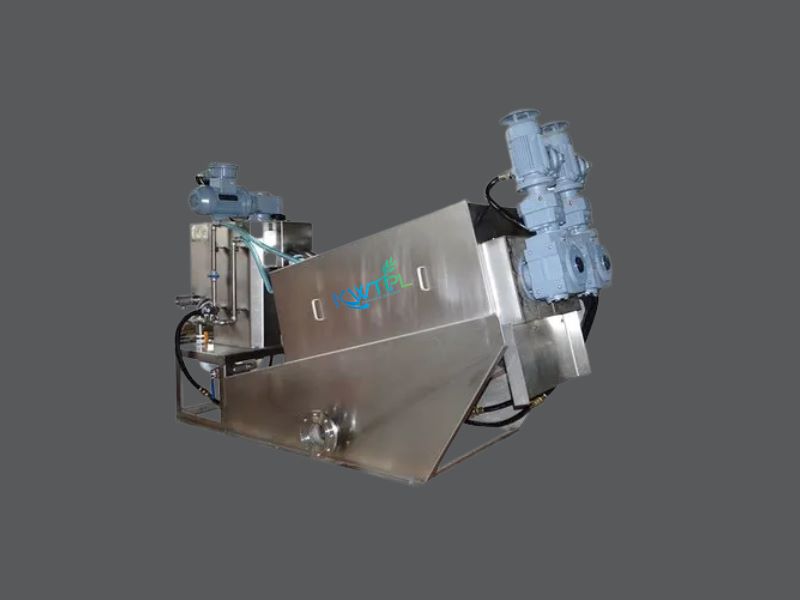

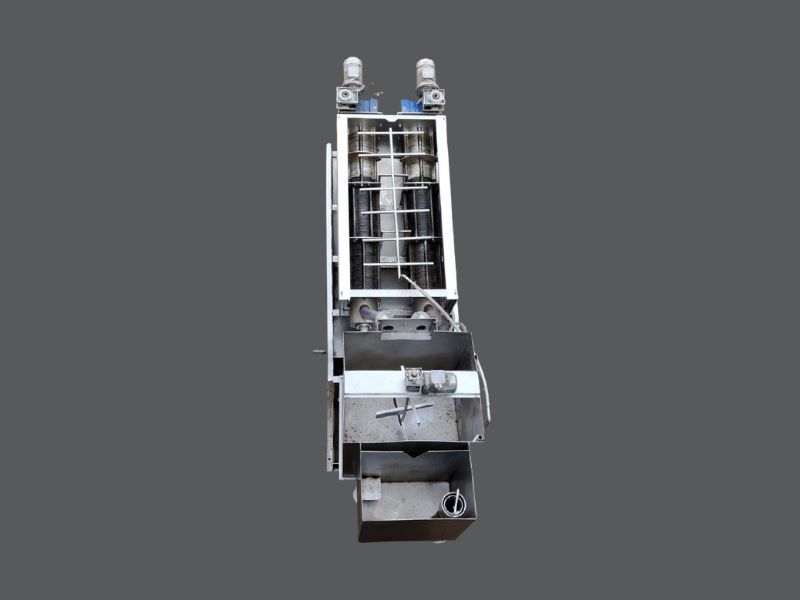

Kelvin's screw press is composed of fully automatic control cabinet, flocculation modulation box, sludge thickening and dewatering device. The machine has an advantage of high pressure generation and it can increase the capacity of the sludge suction so as to reduce manpower consumption significantly.

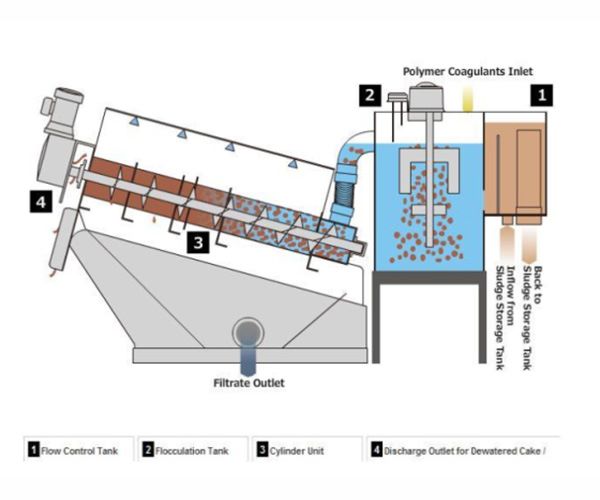

The sludge is delivered to the metering tank through the sludge pump, and then the sludge flows into the flocculation mixing tank. The excess sludge flows back to the sludge tank from the overflow pipe. Inject polymer flocculants into the flocculation mixing tank, alum floc formed after stirring, and then enters into a dewatering section of a screw press after gravity concentration (pre-treatment) section. Flocculation and dewatering are carried out in sequence, so that we have a three-stage separation process: flocculation, dewatering and concentrate recovery.

This series of screw press machines are suitable for the pressing and dewatering of solid materials like sludge and other solids, such as some waste food materials and other industrial wastes. The main body of the screw press can be divided into two parts: in the first part where gravity concentration occurs, the screw will rotate downward and push out a mixture of water and solid materials that are below it. In the second part where there is no gravity concentration, but with pressure generated by the rotating screw, pressure is applied to keep the solid materials pressed between rings so that they can get dehydrated by moisture vaporization during operation.

Kelvin's screw press is composed of fully automatic control cabinet, flocculation modulation box, sludge thickening and dewatering device. The machine has an advantage of high pressure generation and it can increase the capacity of the sludge suction so as to reduce manpower consumption significantly.

Ans. Sludge dewatering is the procedure of reducing waste volume to prepare it for successful disposal. Sludge is formed during the treatment of wastewater before it is released back into the environment. Sludge, a by-product recovered from slurry during the process of industrial or municipal wastewater treatment, has long been a source of concern for the water treatment sector. Dewatering the sludge with a dewatering filter press reduces its weight and volume before disposal significantly.

Ans. Dewatering is the removal of groundwater or surface water from a site, such as a construction site. Water is pumped from wells or sumps during construction to temporarily decrease groundwater levels, allowing excavation in dry and stable circumstances below natural groundwater levels.

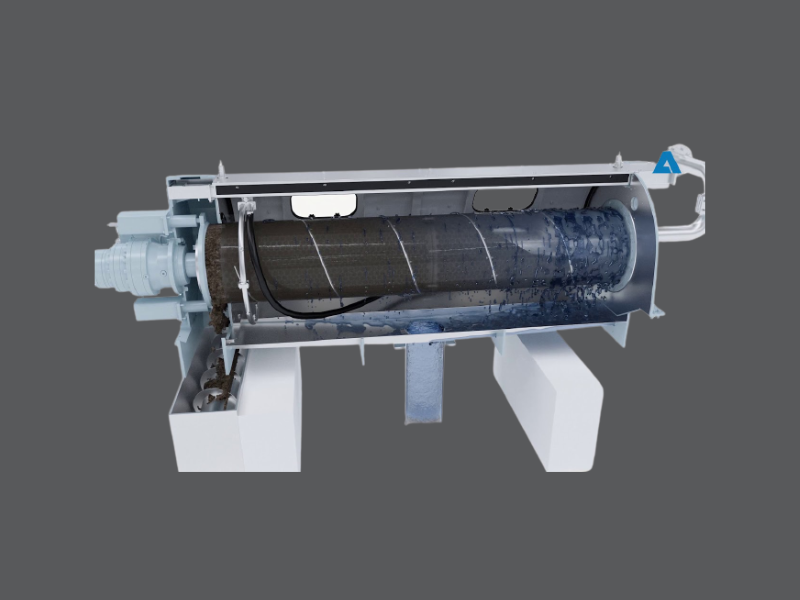

Ans. To separate wastewater liquid from solids, a sludge dewatering centrifuge spins a "cylindrical bowl" quickly. The wastewater centrifuge dewatering process removes more water than other methods while leaving a solid material known as cake behind. Dewatering requires less tank area to hold waste products.

Ans. Sludge Dewatering Benefits -

Ans.Plate and frame filter press, centrifuge, and belt press are the three processes. These approaches are used in wastewater treatment plants, power plants, refineries, and drinking water facilities to minimise sludge volume and make transportation more cost effective.

Ans. The two primary goals of treating sludge before disposal are to minimise its volume and stabilise the organic contents. The odour of stabilised sludge is not objectionable, and it may be handled without causing a nuisance or a health danger. Pumping and storage costs are reduced when the sludge volume is reduced.