-

Water, Waste Water and Organic Waste

Management Company -

email us

info@kelvinindia.in

-

call us now

+91 9812 24 1001

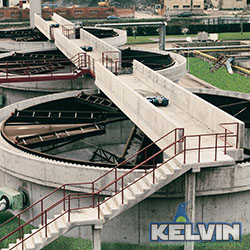

A wastewater treatment plant is an advanced form of traditional facilities such as sewage and effluent treatment plants. In WWTP, a combination of various processes such as physical, chemical and biological are used to treat industrial wastewater. We can also say that WWTP is an extension of STP with additional facilities, functions and treatment calibre.

If the industrial outflow of wastewater is of such hazardous nature that can barely be treated with municipal sewage and effluent treatment plants, then why not opt for Kelvin’s Wastewater Treatment Plants ((WWTP)? Wastewater Treatment Plants can lessen the treatment expenses incurred by municipal sewage treatment plants by reducing the pollutant concentrations in the wastewater and providing resultant water capable of being used for varied purposes.

Large industrial undertakings such as petrochemical sites, petroleum refineries and pharmaceutical laboratories may find the disposal of their wastewater a cumbersome process and simple municipal STP may not be enough to meet their disposal requirement. Hence, in order to comply with the local and national regulations regarding disposal of wastewaters into community treatment plants or into rivers, lakes or oceans, they need WWTP. Other industrial processes that produce a lot of waste-waters such as paper and pulp production has created environmental concern, leading to development of processes to clean and recycle the water so that they adhere to pollution control norms before being disposed-off onto the environment. Hence, the role of industrial wastewater treatment plant is immensely important.

Disinfection is the process of destroying pathogenic micro-organisms by physical means. Disinfection is usually the final stage in the wastewater treatment process in order to limit the effects of organic material, suspended solids, and other contaminants. The primary methods of disinfection in the wastewater treatment process are Ultraviolet Irradiation or Disinfection (UV) and chlorination. Although both methods are acceptable and effective, chlorination is typically the most economical method of disinfection.

Wastewater is collected into an aeration tank, where oxygen is introduced to the sewage. This mix utilizes the bacteria and protozoa that feed on organic matter in the wastewater. After the period of agitation has ended, the sludge will settle to the bottom where it is introduced to sewage in the wastewater into a primary clarifier while the wastewater moves on for further treatment.

Extended Aeration is a variation of the activated sludge process with no primary settling. The Extended Aeration process has a 24 hour aerobic retention time which results in the generation of less excess sludge. Extended Aeration is the most popular biological treatment process in package style wastewater treatment which produces a high-quality effluent with ease of installation, operation, low maintenance, and operational costs.

The coalescence plates (separator used to reduce the distance that an oil droplet travels before it reaches the collection surface) are constructed of materials that are hydrophobic (water repelling) and oleophilic (oil attracting). When the oil droplet comes in contact with the plate, it reaches a space of zero velocity and adheres to the surface. The coalescence surfaces multiply the effectiveness of the natural action of oil and water to separate.

Tertiary treatments are the additional methods and activities applied to polish up the traditional sewage treatment sequence. Tertiary treatment is gaining popularity in industrialized countries and most common technologies are micro filtration or synthetic membranes. The membrane filtration makes the treated wastewater indistinguishable from natural waters. Nitrification and de-nitrification, Ozone treatment, use of Aerobic granulation etc are some of the popular tertiary treatment means and methods in WWTP. The standard tertiary filter system provides filter cell flow division, filtration, air scouring, backwashing, and backwash return of the wastewater.

Ans. A wastewater treatment plant is a facility that uses a variety of methods (physical, chemical, and biological) to treat industrial effluent and remove pollutants.

Ans. Water treatment, often known as water purification, is the process of removing undesired chemicals, biological contaminants, suspended particles, and gases from freshwater. The purification procedure results in potable water that can be used for the intended purpose.

Ans. Five Benefits of Wastewater Treatment are-

Ans. The following are commonly used low-cost treatment techniques for sustainable and cost-effective sanitation and wastewater management: